すべての製品

-

アレキサンダー信頼できるサプライヤー

アレキサンダー信頼できるサプライヤー -

ルイ一緒に仕事できて嬉しいわ

ルイ一緒に仕事できて嬉しいわ

無料のサンプルとクーポンを私に連絡してください.

ワットスアップ:0086 18588475571

ウェイチャット: 0086 18588475571

スカイプ: sales10@aixton.com

24時間オンラインでサポートします

x商品の詳細

| タイプ | 自然な循環 | 使用法 | 発電所 |

|---|---|---|---|

| 構造 | 水管 | プレッシャー | 高圧 |

| 蒸気生産 | 最大 20t/h | スタイル | 水平 |

| 燃料 | 石炭火力 | 出力 | お湯 |

| 設計燃料 | 石炭燃料 | 材料 | 特殊ボイラー用鋼板 |

| 燃料タイプ | コークスオーブンガス | 重さ | 1~20トン |

| 溶融プロセス | EF+LF + VD | UTの標準 | ASTM A388またはEN10228 |

| 材料標準 | ASTM、EN、またはISO | ||

| ハイライト | 最大20t/h ボイラーエコノマイザー,天然循環ボイラーエコノマイザー,発電所熱交換器 |

||

製品の説明

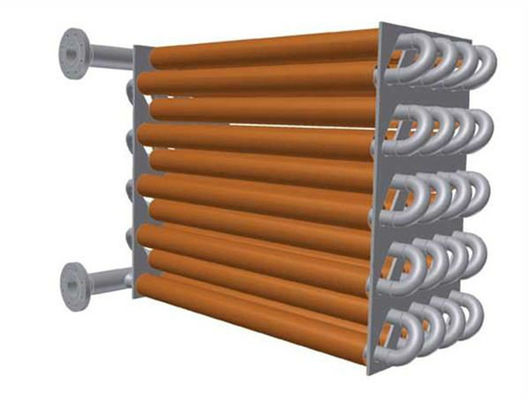

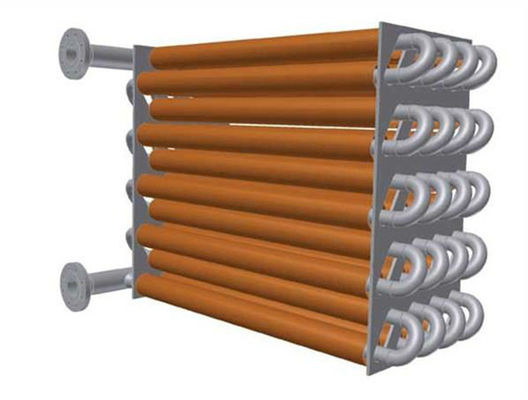

華東暖房システム 品質 安全 ボイラーエコノマイザー

ボイラーエコノマイザーは,液体 (通常は水) を沸点まで,しかしそれを超えないように熱する羽根管を持つ熱交換装置です.私たちは3種類のボイラーエコノマイザーを製造します:

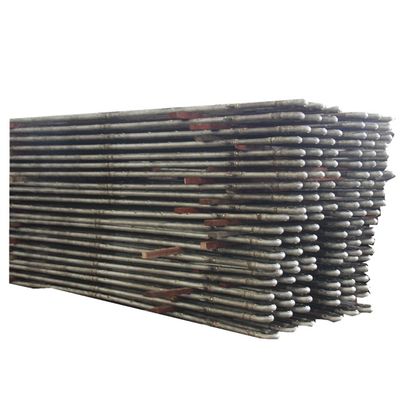

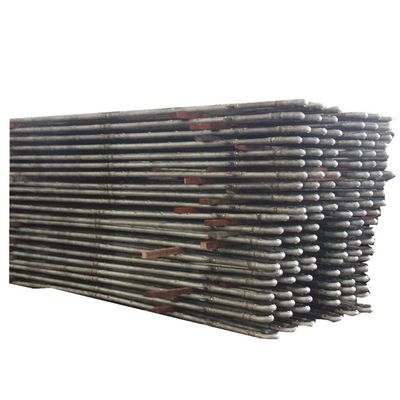

- 裸管エコノマイザー

- Hフィニングチューブエコノマイザー

- スパイラルフィニングチューブエコノマイザー

H-フィニングチューブエコノマイザーは,H-フィニングチューブで構成される高効率の熱交換器である.裸のチューブエコノマイザと比較して,H-フィニングチューブモデルは以下を提供しています:

- 熱交換面積増加

- 必要なチューブの数は少なく

- 流量速度と磨損を減らすために,煙草ガス流域を拡大

長い管列の用途のために高硬度で二重のH翼管として製造できますスパイラルフィニングエコノマイザーは,磨損問題を克服し,使用寿命を延長するために,スパイラルフィニングチューブと新しいデザインを特徴としています.

仕様

| 記述 | ボイラー・エコノマイザー |

| 材料 | 合金鋼,炭素鋼,SA210C,SA213T22など |

| 材料規格 | ASTM,EN,ISOなど |

| サイズ | カスタマイズ |

| 体重 | 10トン - 1000トン |

| 溶融プロセス | EF+LF+VD |

| プロセス | 材料→インゴット→ホット/コールドロール→熱処理 (標準化+テンパー)→検査→粗加工→UT→第2回熱処理→加工→検査 |

| UT標準 | ASTM A388 または EN10228 など |

品質管理

- 衝撃試験と強度計算報告書,適用材料の情報

- 鋼板,管,電極の100% NDT (非破壊検査) 報告

- ボイラーの品質を確保するためのX線,γ線,液体浸透剤試験検査報告書 (溶接シーム)

- 標準作業圧力と安全性を検証するための液圧試験報告

同様の製品

会社情報

証明書

よくある質問

連絡 ください

アドレス:中国江苏省 張江江市 唐里路1号

テレフォン:+86 (0) 512 5866 6196

ファックス:+86(0) 512 5877 4453

ウェブ:www.boilerfabrication.com