すべての製品

-

アレキサンダー信頼できるサプライヤー

アレキサンダー信頼できるサプライヤー -

ルイ一緒に仕事できて嬉しいわ

ルイ一緒に仕事できて嬉しいわ

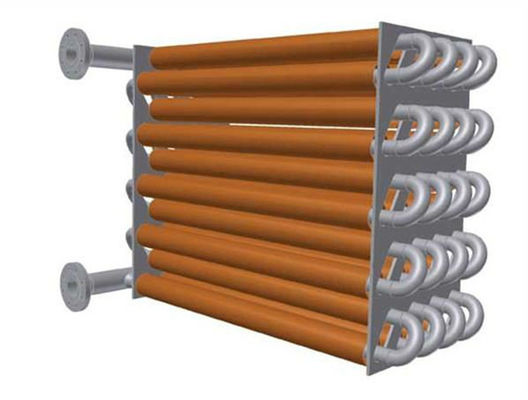

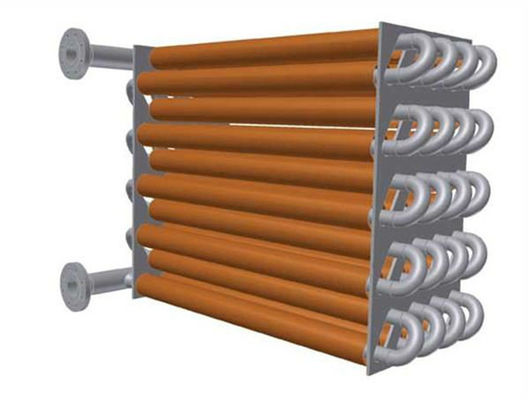

フィン付きチューブを備えた排ガスボイラーエコノマイザー熱交換器(最大蒸気発生量120t/h、自然循環、1年保証)

無料のサンプルとクーポンを私に連絡してください.

ワットスアップ:0086 18588475571

ウェイチャット: 0086 18588475571

スカイプ: sales10@aixton.com

24時間オンラインでサポートします

x商品の詳細

| タイプ | 自然な循環 | 構造 | 火管と水管 |

|---|---|---|---|

| プレッシャー | 低い/高圧 | 蒸気生産 | マックス。 120t/h |

| スタイル | 垂直 | 燃料 | 石炭 / ガス / 石炭火力 / 水温 |

| 出力 | 熱湯/蒸気 | 材料 | 炭素鋼、ステンレス鋼、合金鋼 |

| 材料標準 | ASTM、EN、またはISOなど | 重量範囲 | 分:最大10トン:1000トン |

| 溶融プロセス | EF+LF + VD | プロセス | マテリアル - >インゴット - >ホット/コールドローリング - >熱処理(正規化+焼き戻し) - >検査 - >ラフマシン - > UT-> 2回目の熱治 |

| UTの標準 | ASTM A388またはEN10228など | 熱交換器タイプ | h-finnedチューブエコノマイザー |

| チューブタイプ | ダブルHフィン付きチューブ | ||

| ハイライト | 最大120t/h蒸気発生量ボイラーエコノマイザー,1年保証熱交換器,自然循環排ガスエコノマイザー |

||

製品の説明

フィン付きチューブを備えた排ガスボイラーエコノマイザー熱交換装置

製品紹介

ボイラーエコノマイザーは、液体の沸点を上回ることなく液体(通常は水)を加熱するように設計された、フィン付きチューブを備えた高効率の熱交換装置です。当社は3種類のボイラーエコノマイザーを製造しています。

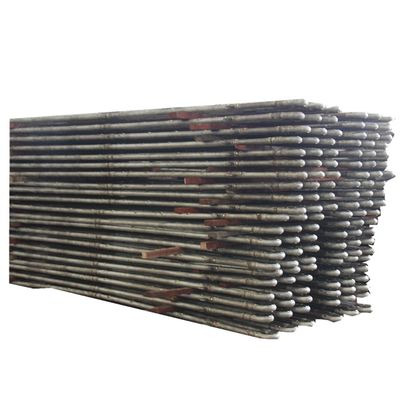

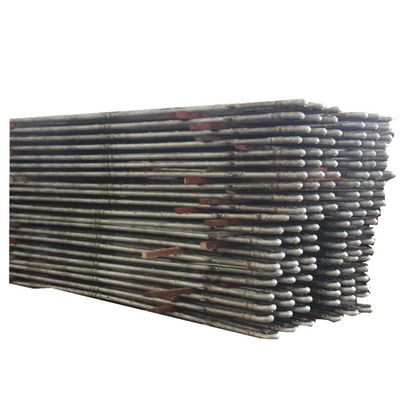

- ベアチューブエコノマイザー

- H型フィン付きチューブエコノマイザー

- スパイラルフィン付きチューブエコノマイザー

H型フィン付きチューブエコノマイザーは、H型フィン付きチューブで構成された特に効率的な設計です。ベアチューブエコノマイザーと比較して、H型フィン付きチューブモデルにはいくつかの利点があります。

- 熱交換面積の増加

- 必要なチューブ数の削減

- 流速と摩耗を減らすための排ガス流路の拡大

- 長いチューブ列での剛性を高めるためのダブルH型フィン付きチューブ構成で利用可能

スパイラルフィンエコノマイザーは、摩耗の問題に対処し、耐用年数を延長するスパイラルフィンチューブを備えた、当社の最新の設計革新を表しています。

技術仕様

| 説明 | ボイラーエコノマイザー |

|---|---|

| 材質 | 合金鋼、炭素鋼、SA210C、SA213T22など |

| 材料規格 | ASTM、ENまたはISOなど |

| 寸法 | カスタマイズ |

| 重量 | 最小:10トン 最大:1000トン |

| 製錬プロセス | EF+LF + VD |

| プロセス | 材料→インゴット→熱間/冷間圧延→熱処理(正規化+焼戻し)→検査→粗加工→UT→2回目の熱処理→仕上げ加工→検査 |

| UT規格 | ASTM A388またはEN10228など |

品質管理

- 適用材料情報を含む衝撃試験および強度計算レポート

- 鋼板、チューブ、電極の100%NDT(非破壊検査)レポート

- 完全なボイラー品質を確保するためのX線、γ線および浸透探傷検査レポート(溶接シーム)

- 標準使用圧力と安全性を検証するための油圧試験レポート

製品ギャラリー

会社情報

認証

梱包と発送