すべての製品

-

アレキサンダー信頼できるサプライヤー

アレキサンダー信頼できるサプライヤー -

ルイ一緒に仕事できて嬉しいわ

ルイ一緒に仕事できて嬉しいわ

最大20t/h蒸気生産量、主要部品5年保証の省エネボイラーエコノマイザー

無料のサンプルとクーポンを私に連絡してください.

ワットスアップ:0086 18588475571

ウェイチャット: 0086 18588475571

スカイプ: sales10@aixton.com

24時間オンラインでサポートします

x商品の詳細

| タイプ | 自然な循環 | 構造 | 火管と水管 |

|---|---|---|---|

| プレッシャー | 低い/高圧 | 蒸気生産 | 最大 20t/h |

| スタイル | 垂直 | 燃料 | 石炭 / ガス / 石炭火力 / 水温 |

| 出力 | 熱湯/蒸気 | 表面処理 | 塗装 |

| 材料 | 合金鋼、炭素鋼、SA210C、SA213T22 | 材料標準 | ASTM、EN、またはISO |

| 重量範囲 | 分:10トン、最大:1000トン | 溶融プロセス | EF+LF+VD |

| プロセス | マテリアル - > ingot-> hot/cold-rolling->熱処理 - >検査 - >ラフマシン - > ut-> 2番目の熱治療 - >仕 | UTの標準 | ASTM A388またはEN10228 |

| 熱処理 | 正規化+強化 | ||

| ハイライト | 最大20t/h蒸気発生量ボイラーエコノマイザー,排ガスエコノマイザー1年保証,熱交換器の主要部品5年保証 |

||

製品の説明

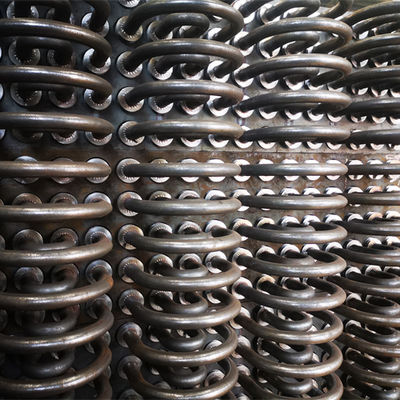

エネルギーを節約する排気ガスボイラーエコノマイザー 螺旋フィンチューブ

ボイラー用スペアパーツ 排気ガス ボイラー機器 エコノマイザー

製品紹介

ボイラーエコノマイザーは,高効率の熱交換装置で,液体の沸点を超えない状態で液体 (通常水) を加熱するように設計されたペニント管である.我々はボイラー経済化器の3種類の製造:

- 裸管エコノマイザー

- Hフィニングチューブエコノマイザー

- スパイラルフィニングチューブ・エコノマイザー

H-フィニングチューブエコノマイザーは,H-フィニングチューブで構成される特に効率的な熱交換器である.裸のチューブエコノマイザと比較して,H-フィニングモデルは以下を提供しています:

- 拡張された熱交換領域

- 必要なチューブの数を減らす

- 煙草ガス流量面積の増加

- 煙草ガス流量速度と磨きが低下する

私たちの螺旋翼エコノマイザーは 螺旋翼管の革新的なデザインで 摩擦や短寿命の 共通の問題を克服します

製品機能

その名前の通り,エコノマイザーの主な機能は"節約"です. 十分な冷却容量を維持しながらコンプレッサーをシャットダウンさせることで冷却コストを大幅に削減します.相当なエネルギー節約をもたらす.

テクニカル仕様

| 記述 | ボイラー・エコノマイザー |

|---|---|

| 材料 | 合金鋼,炭素鋼,SA210C,SA213T22など |

| 材料規格 | ASTM,EN,ISOなど |

| サイズ | カスタマイズ |

| 体重 | 最低10トン 最大:1000トン |

| 溶融プロセス | EF+LF + VD |

| プロセス | 材料→インゴット→ホット/コールドロール→熱処理 (標準化+テンパー)→検査→粗加工→UT→第2回熱処理→加工→検査 |

| UT標準 | ASTM A388 または EN10228 など |

品質管理

- 衝撃試験と強度計算報告書,適用材料の情報

- 鋼板,管,電極の100% NDT (非破壊検査) 報告

- X線,γ線,液体浸透剤の検査報告書 (溶接シーム) 完全なボイラーの品質を確保するために

- 標準作業圧力と安全性を検証するための液圧試験報告

製品画像

会社情報

認証

梱包 と 輸送