-

アレキサンダー信頼できるサプライヤー

アレキサンダー信頼できるサプライヤー -

ルイ一緒に仕事できて嬉しいわ

ルイ一緒に仕事できて嬉しいわ

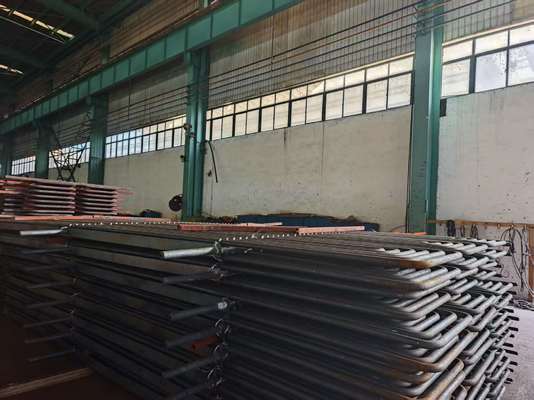

Anti Corrosion Carbon Steel Superheater - Coal Fired CFB Power Plant Boiler Parts

無料のサンプルとクーポンを私に連絡してください.

ワットスアップ:0086 18588475571

ウェイチャット: 0086 18588475571

スカイプ: sales10@aixton.com

24時間オンラインでサポートします

x| 特徴 | 高温耐性,腐食耐性,耐久性,カスタマイズ可能 | 材料 | 炭素鋼,合金鋼,不鋼鋼,ニッケル合金,ハステロイ,インコネル,インコローイ,デュプレックス鋼,スーパーデュプレックス鋼 |

|---|---|---|---|

| コイルの長さ | カスタマイズされた | コイル材料 | 炭素鋼,合金鋼,不鋼鋼,ニッケル合金,ハステロイ,インコネル,インコローイ,デュプレックス鋼,スーパーデュプレックス鋼 |

| 表面処理 | 塗装,加熱,粉末塗装,磨き | 形 | ストレート,U型,蛇形 |

| アプリケーション | ボイラー,発電所,石油化学,精製,化学,紙とパルス,繊維,砂糖,製薬,食品加工 | サイズ | カスタマイズされた |

| コイル表面処理 | 塗装,加熱,粉末塗装,磨き | コイルの種類 | 裸で フィン |

Anti Corrosion Carbon Steel Superheater - Coal Fired CFB Power Plant Boiler Parts

Description

For power plant boiler, it is a crutial way to increase thermal economy of thermal power station by improving parameter of superheated steam. The increase of superheated steam parameters are limited by metal materials. The design of superheaters must make sure that the temperature of outer wall of heating surface pipes is lower than allowable temperature of oxidation resistance of steel, and meanwhile make sure its mechanical strength. with the development of metal material used in boilers, power station boilers in our country already generally apply high pressure, high temperature(9.8MPa, 540 degrees) and superhigh pressure parameters(13.7 MPa, 540 and 555 degrees), and have developed subcritical pressure parameters(16.7MPa, 540 and 555 degrees). Now lots of boilers apply supercritical pressure parameters(24.5MPa, 540-570 degrees), and even very few units apply higher pressure and temperture parameters.

![]()

Application

use for heating saturated steam, steam temperature could be up to 900 degree C.

Superheater Capacity Upgrades to Increase Power Generation

Send us required technical data, such as steam capacity, presure, required temperature etc. We will design accordingly.

Differences

| Type | Advantages | Disadvantages | Supporting method |

| Pendant-type | 1.Firm structural support | 1. Flow blockage by condensed steam 2. Needs slow restart to purge the water that accumulates in the bottom. | supported from above |

| Inverted-type | 1.Proper drainage of the condensed steam | 1. Lack the structural rigidity, especially in high speed gas flow | Supported from below |

| Horizontal -type |

1. Proper drainage 2. Good structural rigidity. |

1. They do not view the flam directly so they are mainly from the convective type | Usually supported in the vertical gas ducts parallel to the main furnace. |